Five Reasons Why Grating is Better

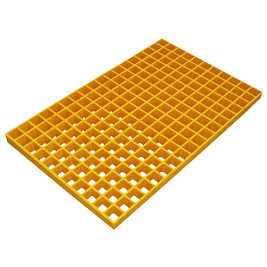

Anti Slip Grating is a fixed framework of bars or similar structures that covers an entrance to keep out people, animals, objects, and coarse material while allowing air, light, or fine material to pass through.

Panels of grating are another option, and these are frequently used for the decks of footbridges, catwalks, and bridges. Steel, aluminum, and fiberglass are a few materials that can be used to make grating. FRP grating is another name for fiberglass grating. They are used to reduce weight while improving bending stiffness.

Types of grating:

Different types of grating are as follows:

Steel Grating:

In situations where hygienic as well as anticorrosive gratings are required, stainless steel panels are preferred. Industries like food processing, pharmaceuticals, chemicals, offshore platforms, petrochemicals, water treatment facilities, hydro processing, and distilleries are the principal users of stainless steel gratings.

Standard Grating:

Platform gratings that have been welded together are constructed from parallel-carrying flat plates that are linked transversally by rounded bars with grooves, resulting in a single surface at the grating's top.

Heavy-duty Grating:

Gratings for heavy-duty applications are made to withstand both heavy rolling and static loads. Heavy-duty gratings are produced in a variety of carrying bar sizes and spacings because traffic conditions can vary from light to heavy. It is widely employed in mining, the production of electricity, on highways, at airports, and on loading docks, but also on ramps at truck terminals.

Wire-mesh Metal Grating:

Other common names for wire mesh Anti Slip Grating include wire grating, wire cloth, wire fabric, etc. Wires that cross in rows and columns are used to create this kind of metal grating. The ease of installation, great durability, flexibility, and adaptability of wire mesh grating contribute to its widespread use. When the rows and columns intersect, welded-wire metallic grating is used. The woven wire metal grating, on the other hand, is woven like cloth and contains a variety of connecting wires with rows and columns across and under as their connection places.

Serrated Grating:

In the case of such a serrated grating, a bearing flat bar with trapezoidal slices is used.Because it has a higher non-skid level than other gratings, it is frequently used in hazardous areas, including slippery floors and walkways.

Trench Grating:

Trench gratings are used in shallow excavations at industrial sites where surface drainage is necessary, such as around swimming pools, sidewalks, both residential and commercial areas, and peripheral areas. Moreover, they are used in subterranean parking structures in both commercial and residential structures.

5 Reasons to Use Grating:

- The material that we used is durable, is far more maintenance-free, and is resistant to the effects of the outside environment.

- When we discuss the criteria that must be upheld in buildings, we are referring to adhering to a number of very strict laws and guidelines.

- Fiberglass is a safer material. Fiberglass is an excellent thermal insulator.

- The most important thing when we choose the material is price and cost.

- Materials are designed to be exceptionally strong and resistant.

Comments

Post a Comment