Advantages of Slip-Resistant Grating

A grating is any regularly spaced collection of almost identical, parallel, elongated components. Any regularly spaced group of nearly identical, parallel, elongated components is referred to as a Grating. The lines serve as opaque gaps that prevent incident light from passing through. The area in between the two lines functions as a slit and is transparent to light.

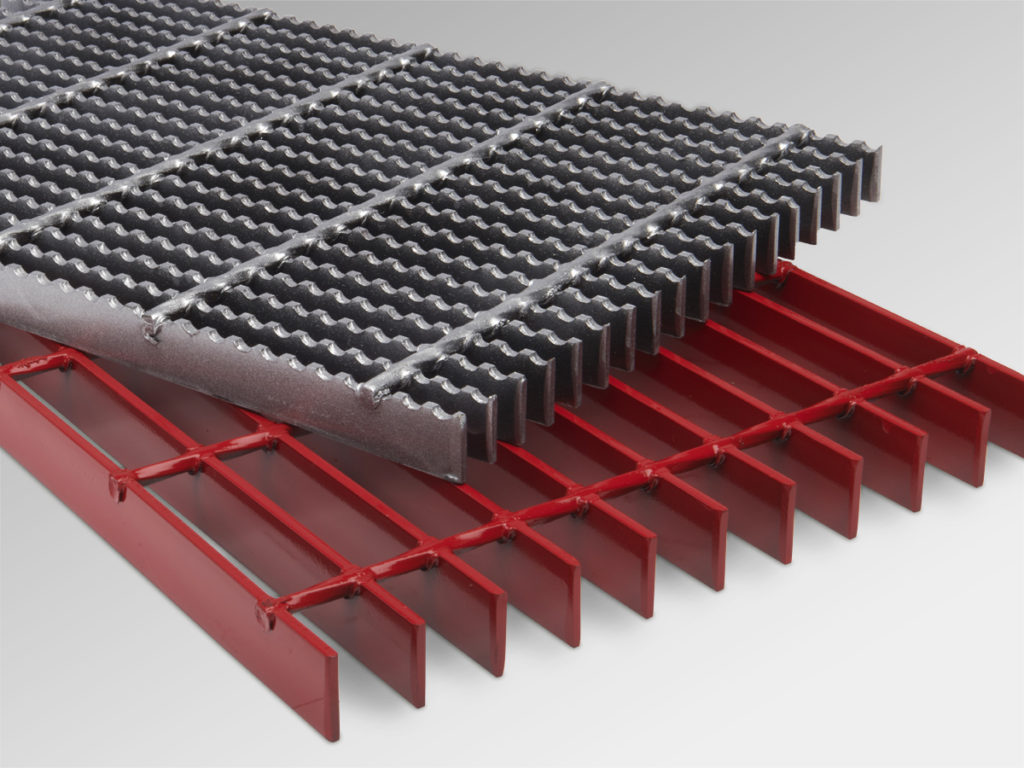

Iron, carbon steel, aluminum, and stainless steel are the metals that are most frequently used to create metal gratings. Metal gratings that serve as a safe work platform must be strong enough to support the load and have a non-slip surface.

Advantages:

Corrosion and Chemical Resistance:

Gratings are corrosion and Chemical Resistant. It is possible to define corrosion resistance as the capacity to prevent corrosion on the substrate. Two of the most frequent reasons for unplanned equipment downtime are corrosion and chemical assault, and damage can be caused by a variety of things, including fluids, cleaning supplies, and saltwater. By forming a nonporous protective covering on metal substrates, our coatings efficiently fend off these dangers, lowering the need to replace metal components while extending their lives. Corrosion shortens the lifetime of tools and products and necessitates more regular calibration checks and equipment maintenance.

High Resistance:

High-strength concrete manufacturers are aware of the variables that determine the compressive strength and are skilled in their manipulation. Stronger concrete columns can be constructed thinner than ordinary-strength concrete columns because they can support greater weight. This creates more usable space, particularly on lower floors of structures. The procedures and technologies required to manufacture high-strength concrete are not all that distinct to those required to manufacture standard-strength concrete. Good-strength steel has several advantages, including high item quality, gratings with high return strength, and the possibility to conserve weight by employing a slenderer material.

Impact Resistance:

The ability of a material to sustain a quick, powerful force or shock is referred to as "impact resistance." When concrete is subjected to regular shock loads or impact loads, impact resistance is crucial to how well it performs. Tough materials like Non Slip Grating by nature more impact-resistant than some other materials; however, a material's impact resistance can vary depending on a number of circumstances.

Fire Resistance:

A fire-resistant system's fire-resistance rating typically refers to how long it can sustain a normal fire-resistance test. Minutes are used to measure fire resistance. This has to do with the time that has passed during a typical test and is not to be confused with actual time. Our gratings are designed with fire resistance in mind, making them both fire resistant and capable of providing fire resilience to the built environment. The ability to resist fire, flame projectiles, fire charges, lava blocks, and lava damage.

Ergonomic:

An applied science focused on creating and arranging objects that people use in order to maximize the effectiveness and safety of human-object interactions The ergonomic grating stand is intended to give your employees' workstations a sturdy, non-slip, adjustable stand. Chips and liquids can fall underneath the standing surface due to the open mesh grating and the raised space generated by the rubber feet.

Comments

Post a Comment