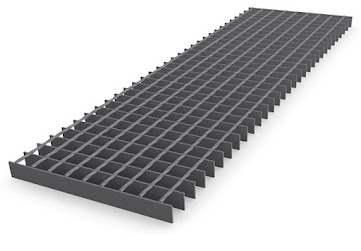

Installation and Care of Grating

A barrier with horizontal or vertical bars that is airtight but blocks passage. For the grating to meet the strength requirements, crossroads must be put on the top side. Grating can have two sets, in which case the second set is typically perpendicular to the first, but they typically only have one set of elongated pieces. The two sets are also referred to as a grid and a mesh when they are perpendicular. The supports for all gratings should be made of metal.

Metal gratings are frequently used for subway tiles, plant construction, street fences, and building decorations, among other applications, due to their great performance. This forces us to concentrate on the regular upkeep and repair of metal gratings in order to increase their lifetime and utility.

Care of Grating

- The long-term health of floor grating depends on routine maintenance. No grill now on the market maintains itself in ideal condition without routine cleaning and maintenance. Grating experiences significant wear and tear and requires ongoing maintenance.

- When performing routine cleaning, protected areas should receive extra attention to ensure that any buildup of airborne contaminants is eliminated. This is crucial in marine and industrial settings, where the accumulation of airborne chlorides can cause localized corrosion if they are not properly eliminated.

- The slightly heavier soil can be removed with soap and water, rags, a bristle brush, a soft brush, or a broom. Use regular, mild household detergents. Scrub after using soap and water.

- Rinse with water and allow to drip dry.

- To maintain the stainless Steel Grating attractive surface and increase its lifespan, routine cleaning and maintenance are required. When cleaning the stainless steel grating's surface, caution must be exercised to avoid scratching it. Avoid using steel wire balls, harsh instruments, and other bleaching and abrasive cleaning agents. After cleaning is complete, rinse the surface with clean water to remove the washing liquid.

Installation of Grating:

- The best way to install grating panels is to lay them across a support beam and secure them with the correct clamps.

- Before the installation and erection, it must be possible to easily access documents of the materials' quality inspection, such as receipt inspections or fabrication approval drawings, for site references.

- If the customer doesn't have any particular requests, the clip will be provided in accordance with the four numbers on every piece of the grating. The higher clips and the lower and upper clips are the two categories into which the clips are separated. Bolts, nuts, and washers are included in both categories.

- Install the upper clip: On the Steel Grating upper surface, attach the upper clip. In the steel grating, saddles are positioned so that they link two neighboring bearing bars.

- Install the lower clip: Attach the lower clip to the steel grating's lower surface and up against the steel grating's support beam. Saddles and associated bearing bars are tightly buckled. It should be noted that the upper and lower clip holes must line up.

- Install bolts and nuts: After the lower and upper clips have been placed correctly, tighten the nuts on the upper as well as lower clips by inserting the bolts through the bolt holes.

Comments

Post a Comment