Grating Compliance with Safety Standards

In industrial and commercial settings, where safety is a main concern, guaranteeing that Grating conforms to safety standards is urgent. The plan, assembling, and establishment of grating assume a critical part in gathering laid out safety rules. This article will dig into the significance of grating compliance with safety standards, the particular prerequisites that should be met, and the advantages of picking safety-agreeable grating for different applications.

Adhering to Regulatory Requirements

Safety standards for grating are in many cases illustrated by administrative bodies and associations that administer word related safety and health. Sticking to these standards isn't simply a lawful necessity however a basic part of establishing a protected work space. Compliance guarantees that the grating meets the fundamental rules to forestall mishaps and wounds.

Material Selection for Durability and Safety

Safety-consistent grating starts with the determination of materials that satisfy explicit safety guidelines. Normal materials incorporate steel, aluminum, and fiberglass, each with its own arrangement of properties. The picked material should not just endure the ecological states of the application yet in addition add to a free from even a hint of harm working surface.

Load-Bearing Capacity and Structural Integrity

Safety standards frequently incorporate details for load-bearing limit and primary honesty. Grating should have the option to endure the normal burdens without undermining its security. Compliance with load-bearing necessities guarantees that the grating can securely uphold the weight applied to it, forestalling primary disappointments that could prompt mishaps.

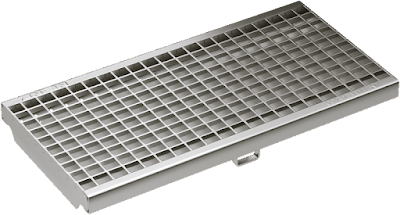

Slip Resistance for Enhanced Safety

Slip resistance is a basic consider safety-consistent grating. Contingent upon the application, the grating surface ought to be intended to diminish the gamble of slips and falls. The joining of anti-slip highlights, whether through surface examples or coatings, is fundamental for fulfill safety guidelines, especially in areas where fluids or oils might be available.

Openings and Spacing for Efficient Drainage

Productive waste is one more perspective covered by safety standards. Grating in areas where fluids are common ought to have openings and dispersing that consider the speedy seepage of water, forestalling the amassing of slippery surfaces. Compliance with seepage prerequisites adds to a more secure work space, particularly in industrial settings.

Corrosion Resistance for Longevity

Safety-agreeable Steel Grating is frequently expected to oppose consumption. This is particularly significant in conditions where openness to destructive substances is normal. Guaranteeing that the grating material has consumption safe properties contributes not exclusively to safety yet in addition to the life span and strength of the grating.

Guarding Against Sharp Edges and Protrusions

Safety standards frequently address the potential dangers related with sharp edges and bulges. Compliance expects that grating is planned and produced to limit these dangers. Adjusted or inclined edges, as well as legitimate getting done, add to establishing a more secure workplace by lessening the probability of wounds brought about by contact with sharp components.

Electrical Conductivity Considerations

In specific applications, electrical conductivity might be a variable that safety standards address. Grating in conditions where electrical conductivity is a worry ought to follow explicit rules to forestall the gamble of electric shock or other electrical risks. This is especially important in industrial settings where electrical gear is available.

Accessibility and ADA Compliance

For grating in areas open to general society, compliance with availability standards, for example, those illustrated by the Americans with Handicaps Act (ADA), is vital. This incorporates contemplations for openings, separating, and surface elements to guarantee that people with incapacities can explore the space securely. Safety-consistent grating adds to establishing comprehensive and available conditions.

Advantages of Choosing Safety-Compliant Grating

Picking grating that conforms to safety standards offers various benefits. Past legitimate compliance, these advantages incorporate a diminished gamble of work environment mishaps, upgraded toughness and life span, limited maintenance costs, and a general improvement in the safety culture of the work environment. Safety-agreeable Anti Slip Grating is an interest in both the prosperity of people and the effectiveness of activities.

Conclusion: Prioritizing Safety in Grating Selection

In conclusion, the meaning of grating compliance with safety standards couldn't possibly be more significant. It is a proactive way to deal with guaranteeing a completely safe work space. From material choice to slip resistance and burden bearing limit, safety-consistent grating sets the norm for making spaces where the gamble of mishaps is limited, advancing both specialist prosperity and functional productivity.

Comments

Post a Comment