Steel Symphony: Grating Explorations

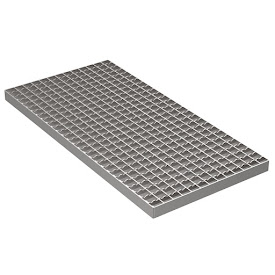

Grating is a high-transparency structural element with a low dead weight and great load-bearing capability. The Grating is not only exceedingly sturdy but also visually appealing, thanks to the positive-fitting attachment of the bearing and cross bars to the surround. Grating is widely utilized in industry and architecture; thus, its uses are quite broad. The grating is an integral heavy industrial platform flooring that is safe, lightweight, and incredibly sturdy. The most common variety is steel grating, which is noted for its strength and flexibility. They are coated in various materials to increase strength or heated to a high temperature to prevent consumption. Industrial areas, walkways, and stages are the typical locations for steel gratings.

Steel grating, also known as metal open bar grating, is one of the most often used types of grating. Steel that has been welded is either stainless steel or carbon steel. Steel grating is strong and capable of carrying heavy loads. It also has an anti-slip surface and resists corrosion. Because of this, it's commonly used as a pathway, floor, ceiling, stair, fence, and shelf. Because steel grating has so many benefits, it is an essential part of many modern and commercial environments. Its versatility and customization choices make it a favored solution for a range of basic and security requirements, contributing to its large and pervasive deployment in various initiatives. Grating is the best choice in scenarios when more than just adequate ventilation and lighting are required as it also considers effective light and wind current transfer. Enhanced waste and ventilation, long-term durability, simple support, and enhanced safety owing to its non-slip surface are some of its primary advantages.

Welded Steel Grating: The welding procedure guarantees that the welded gratings' strength areas are ideal for industrial walkways, channel coverings, and stage applications. Welded gratings are produced by shaping crossbars into a form of bars. Because of this, a sturdy architecture is suitable for demanding applications.

Aluminum Gratings

Handling aluminum during installation is easy due to its lightweight nature. Aluminum gratings are a lightweight substitute that offer superior resistance to erosion. They are often selected for applications where weight is an essential variable, such in aviation or marine trade.

Steel Grating is widely used in many different industries, including the petrochemicals, paper, and dock sectors; it is also used in the manufacturing of weapons, waterpower, energy, and ports and docks. There are many different types of steel gratings, such as press-locked bars, welded steel gratings, heavy-duty, dense, and compound gratings. Steel gratings are also needed for the poultry house floor, gully well, stair tread, platform, and tree pool cover.

Enhanced Steel Fencing

The expanded metal grating may be rapidly and simply welded or bolted into place, making it perfect for usage on worker platforms, catwalks, and plant runways. The most cost-effective and practical solution to guarantee strength, security and a non-skid surface is expanded metal grating.

Stainless Steel Grating

Stainless steel Anti Slip Grating has been the industry standard for walkways in highly corrosive situations for a long time. It is a frequently utilized grating material. It is offered in both welded and press-locked versions, and it is available in a range of bearing bar sizes. The food, water, and chemical processing sectors are the main industries that use stainless steel bar grating.

Comments

Post a Comment